Products

CNC Oil Skimmer

New conceptual oil skimmer

for efficient management of coolant

Using an Oil-Skimming device offers a simple and reliable method of minimizing oil contamination in the metal working fluid and therefore improving the performance of CNC machine tools.

A foul odour, or the “Monday morning smell” is usually the first sign that a bacterial colony has formed in the coolant tank.

CNC Oil Skimmer greatly reduces "smoking" caused by tramp oil.

They can help to increase the coolant change intervals, reduce a hazardous environment for operators from unnecessary fumes, pungent and contaminated coolant.

Product Line-Up

Features

Easy installation

Select the model according to the installation methods

Fixed Type

The CNC "Fixed type" is designed with a magnetic bracket and can be attached on the top of the coolant tank.

Stand Type

The CNC "Stand type" is designed as a stand-alone structure and can be placed on the bottom of the coolant tank.

Powerful Performance

Upgrade your coolant management with CNC Oil Skimmer

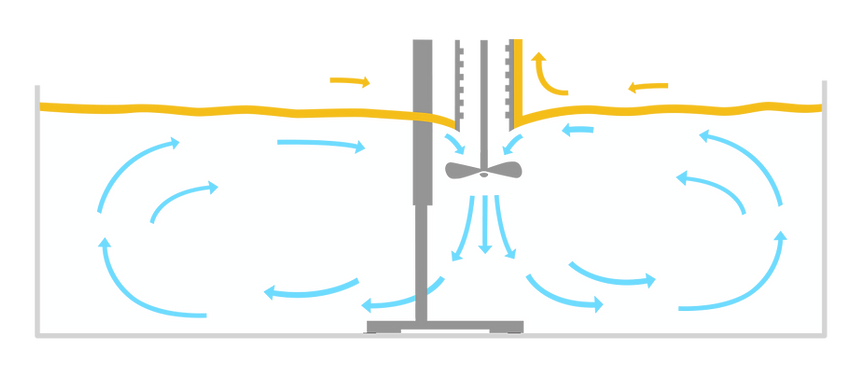

Tramp Oil Removal & Coolant Circulation

Oil removal

Cutting fluid circulation

Quickly drag oil from far away

Oxygen supply

OIL

OIL

with Impeller

: Oil induced inside of the circle

-

Tramp oil is collected around the belt

-

Faster removal of tramp oil

without Impeller

: Oil remained outside of the circle

-

Tramp oil is left away from the belt

-

Slower removal of tramp oil

Efficient Operation

Experience more efficient operation, healthier environment and cost saving through Remote Control

Remote control type

- Model : S240R, S330R, F330R, F450R

- Monitoring the cutting fluid temperature in real time.

- Set-up the impeller Speed and Run Time according to fluid condition.

Display

Monitoring the cutting fluid temperature in real time.

Displaying the status of set-up

Operation

Start/Stop

Run time

Run and Delay repeat operation in 5 modes

Timer

Automatic power off after the set time

( ∞ : Continuous operation)

Morning Clean

Press the button at the end of the day.

You should find cleaner coolant the following morning.

Dial control type

- Model : S240, S330, F330, F450

- Operation efficiently by speed control

a little tramp oil in tank

Recommended

lots of tramp oil in tank

Power

Power On/Off

Applications

Stand type

Fixed type

Videos

Accessories

Standard Accessories

Adapter & Power cable

Remote Control

(S240R, S330R, F330R, F450R only)

Optional Accessories

Oil Guide - Hose Type

Timer

Extension Cable